HIGH SPEED DRAIN CLEANING

Huh? What is high speed drain cleaning you ask?

High speed drain cleaning, or milling as it's sometime called, is a highly effective drain cleaning process when the internal walls of the drain need a good haircut or scraping.

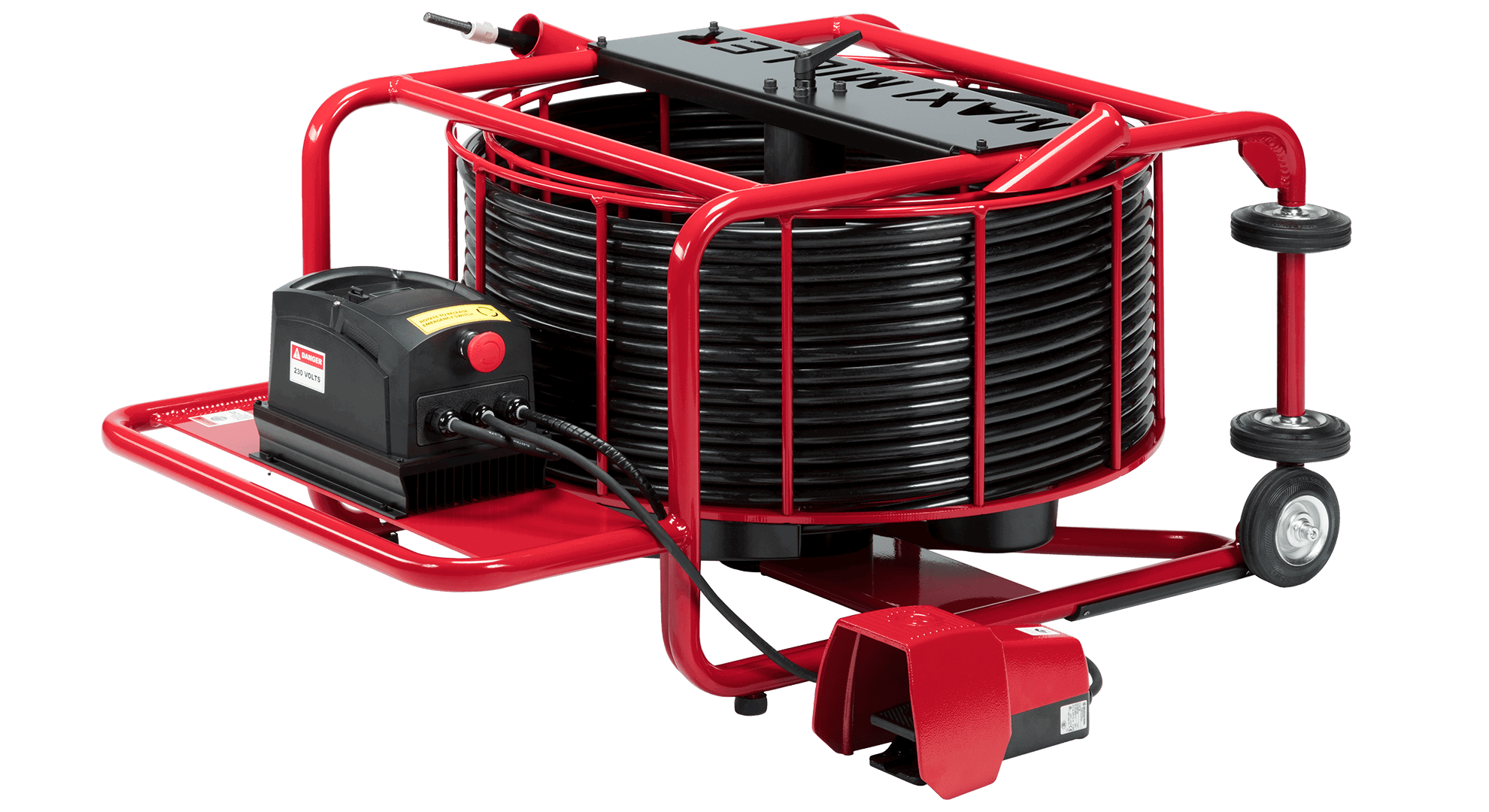

A milling machine has a long metal woven shaft encased in a protective outer sheath driven by a high-speed motor, around 2000rpm to 3500rpm compared to traditional rooters that only spin at about 750rpm.

An assortment of expandable cutters (seen below) are used for the job specific task such as de-scaling or removing tree roots from a drain line. Cutting through grease build-up and roots with greater efficiency than traditional snakes and rooters, it acheives this by allowing the drain technician to visually see the cutter tip with a cctv sewer inspection camera whilst in opperation, something previously not possible.

Expanding cutters allow for full and total cleaning of the drain even when the clean out access is limited in size giving our customers by far unmatched results. There are limitations however, large plugs of roots are best rooted out first and then finished off with either the high speed flexshaft or hydro-jetter to fully remove the rest.

This equipment is always used in conjunction with our drain camera and gives our clients an opportunity to what we like to call “see the clean” technology, giving peace of mind that their drains are fully flowing at the optimal rate.